Composite Fencing: Costs, Installation Tips, and Long-Term Value

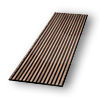

News-Composite fencing uses a blend of recycled plastics and wood fibers (or similar engineered mixes) to create fence boards and rails that resist rot, insects, and many common “wood fence” headaches. If you want a privacy fence that looks consistent year to year with lower upkeep, composite fencing is often the most practical upgrade—especially in wet, high-sun, or coastal environments.

What Composite Fencing Is and Why It Performs Differently

Composite fencing is manufactured rather than milled, which is why it tends to stay straighter and more uniform than natural wood. Many composite systems use capped boards (a protective outer layer) that improve stain resistance and color stability. In practical terms, the “performance difference” shows up in three places: moisture absorption, surface durability, and long-term appearance.

Where composite typically outperforms wood

- Rot and insect resistance: composite boards are not a food source for termites and generally do not rot like untreated wood.

- Lower maintenance: most composite fencing needs periodic washing rather than staining/sealing cycles.

- Consistency: engineered boards reduce knots, splitting, and warping that drive early wood-fence repairs.

Where composite may be a trade-off

- Upfront cost: composite fencing is usually priced above basic wood panels.

- Thermal movement: composites can expand/contract with temperature; correct spacing and fastening matter.

- Impact repair: a damaged board is often replaced rather than “patched” like wood.

Practical takeaway: composite fencing is most compelling when you value stable appearance and lower ongoing maintenance over the lowest initial price.

Composite Fencing Cost: A Realistic Budget Framework

Composite fencing costs vary by board profile (solid vs hollow), cap layer, height, gate hardware, post type, and local labor rates. A practical way to budget is to split your estimate into three buckets: materials, foundation/posts, and installation labor.

Typical cost ranges to plan with

For many residential projects, a planning range of $35–$70 per linear foot installed is common for composite privacy fencing systems, depending on region and specifications. Premium profiles, taller heights, and complex layouts can push higher.

| Fence Type | Planning Installed Cost (per linear foot) | Maintenance Pattern | Best Fit |

|---|---|---|---|

| Pressure-treated wood | $20–$45 | Stain/seal cycle; board replacement over time | Lowest upfront budget |

| Vinyl | $25–$55 | Wash; potential brittleness in extreme cold | Clean look; low upkeep |

| Composite fencing | $35–$70 | Wash; occasional spot cleaning | Long-term appearance + durability |

Example budget math (so you can sanity-check quotes)

If you’re fencing 150 linear feet of privacy fence and the installed range is $35–$70/ft, the project total typically lands between $5,250 and $10,500. Add more if you have multiple gates, retaining walls, steep slopes, or demolition/haul-off needs.

Choosing the Right Composite Fence System

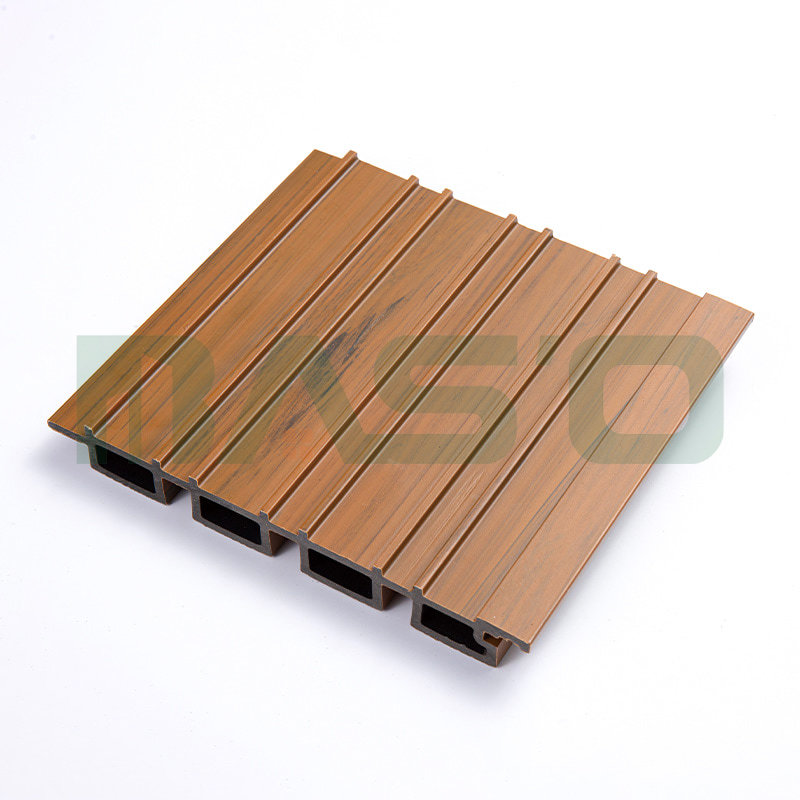

Composite Fence Panel is sold as a system: boards, rails, posts (often steel or aluminum), and proprietary brackets. The system matters because the weak point is rarely the board itself—it’s usually posts, fasteners, or water management at ground level.

Key specification decisions

- Board construction: capped composites typically resist staining and UV fade better than uncapped boards.

- Profile: solid boards generally feel more rigid; hollow profiles can reduce weight and cost but may need reinforcement in high-wind zones.

- Post strategy: many high-performance installs use steel posts with sleeves for a cleaner look and stronger structural core.

- Color and heat: darker colors can run hotter in direct sun, which can increase thermal movement; verify spacing requirements.

Quick “fit test” for composite fencing

Composite fencing is usually a strong match if at least two of these are true: your yard has high moisture exposure, you want a consistent modern look, you do not want stain/seal maintenance, or you plan to stay long enough to benefit from reduced repair cycles.

Installation Details That Determine Long-Term Results

Composite fencing can look excellent—or fail early—based on layout, post setting, and movement allowances. The goal is to build a structure that stays plumb and lets the boards “move” without buckling.

Post spacing and wind planning

Most privacy fences use post spacing around 6–8 feet, but local wind requirements, fence height, and the specific composite system can change that. Taller fences and high-wind corridors often justify tighter spacing and stronger posts.

Concrete footings: where shortcuts show up later

- Set posts to the correct depth for local frost conditions; shallow footings increase heave and leaning.

- Keep the top of concrete slightly crowned or sloped away from the post to reduce standing water.

- Verify gate posts are reinforced; gates concentrate load and are the first place “almost good enough” work fails.

Thermal expansion: simple practices that prevent warping

- Use manufacturer-recommended end gaps and bracket spacing; composites need room to expand.

- Keep boards off soil contact; ground contact increases staining risk and can trap moisture.

- Align fasteners cleanly and avoid over-tightening where the system is designed to “float.”

Practical takeaway: the best-looking composite fencing is usually the best-engineered composite fencing—straight posts, correct spacing, and controlled movement.

Maintenance and Cleaning That Protects Appearance

Composite fencing is low maintenance, not “no maintenance.” The most common issues are surface dirt, pollen film, sprinkler mineral deposits, and organic staining from leaves or mulch.

A simple maintenance schedule

- Monthly (in dusty/pollen seasons): rinse with water to prevent film buildup.

- Quarterly: wash with mild soap and a soft brush for traffic areas and near sprinklers.

- Annually: inspect post plumb, gate sag, and hardware tightness; lubricate hinges if needed.

Cleaning tips that reduce risk

Avoid harsh solvents unless the manufacturer explicitly permits them. If you use a pressure washer, keep pressure conservative and maintain distance to prevent surface etching. For stubborn spots, test any cleaner on an inconspicuous area first.

Practical takeaway: regular light cleaning preserves color uniformity better than occasional aggressive cleaning.

Composite Fencing Design Options That Add Practical Value

Composite fencing is often chosen for privacy, but smart design can also improve airflow, reduce wind load, and enhance street-side curb appeal. The best designs balance function and structure rather than focusing only on aesthetics.

High-value design choices

- Mixed infill: use privacy panels in key sightlines and semi-open sections where airflow is beneficial.

- Topper accents: lattice or slatted toppers can increase perceived height without creating a solid wind sail.

- Contrasting posts/frames: darker posts with lighter boards (or the reverse) highlight clean geometry and hide minor dust.

Gate planning (where usability is won or lost)

Gates should be sized for what you actually move—trash bins, mowers, bikes, or equipment. A common planning rule is one standard access gate plus at least one wider utility gate where needed. In composite fencing, gate framing and post reinforcement are more important than the panel material.

Common Mistakes to Avoid When Buying or Installing Composite Fencing

The most expensive fence is the one you pay to fix. Composite fencing is engineered, so errors often happen when installers treat it like wood and ignore system requirements.

Mistakes that drive callbacks

- Skipping movement gaps and fastening rules, leading to buckling during hot weather.

- Underbuilding gate posts or using light-duty hinges, causing sag and latch misalignment.

- Setting boards too close to soil or mulch, increasing staining and trapping moisture at the bottom edge.

- Ignoring drainage and grade changes, resulting in uneven gaps or water pooling at posts.

Practical takeaway: choose a composite fencing system with clear installation guidelines and insist they are followed.

A Short Checklist for Comparing Quotes

When two composite fencing quotes differ substantially, the difference is often hidden in posts, concrete, gates, demolition, or hardware. Use this checklist to confirm you’re comparing like-for-like.

- Post type and spacing: steel core vs wood; stated spacing (e.g., 6 ft vs 8 ft) and any wind considerations.

- Footing depth and concrete quantity: confirm local frost/wind requirements are accounted for.

- Board profile and cap: capped vs uncapped; solid vs hollow; stated warranty terms for fading/staining.

- Gates: size, frame reinforcement, hinge/latch grade, and whether gate hardware is included.

- Scope clarity: demolition/haul-off, site grading, and cleanup responsibilities.

Final takeaway: composite fencing is a long-term asset when it is specified as a system, installed with movement allowances, and maintained with simple routine cleaning.

Español

Español