Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeown...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averag...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and ins...

READ MORE -

Wood does absorb sound, but its effectiveness is limited compared to specialized acoustic materials....

READ MORE -

Decking accessories are what turn “boards on joists” into a finished deck When a deck looks great o...

READ MORE -

When you’re choosing between a composite and vinyl fence, the “right” answer depends less on market...

READ MORE

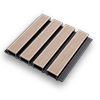

The Durability Advantage of Composite Decking Boards

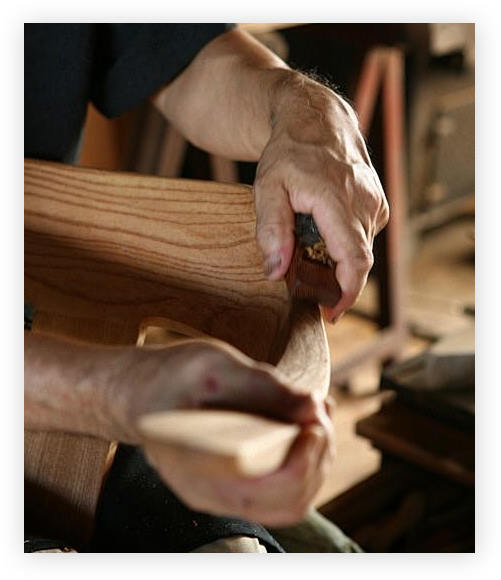

Composite decking boards combine wood fibers with high-quality plastics to create a product that offers superior durability compared to traditional wood. This hybrid structure reduces the risk of warping, cracking, or splintering, making it ideal for outdoor applications. In our factory, we produce composite decking that meets international quality standards, ensuring long-lasting performance even under extreme weather conditions.

Thanks to the combination of materials, composite decking boards also resist mold, mildew, and insect damage. Their low-maintenance nature makes them especially attractive for homeowners and commercial projects, reducing the need for sanding, painting, or sealing while maintaining a natural wood appearance.

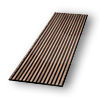

Composite Wall Cladding: Modern Solutions for Facades

Composite wall cladding panels provide an effective solution for enhancing building facades, offering both aesthetic appeal and practical protection. The combination of wood fibers and plastic ensures that cladding panels resist weathering, UV exposure, and moisture absorption. This is critical in preserving the original color and structural integrity over time.

In our production facility, we utilize precision extrusion techniques to create panels with consistent thickness and surface texture, enabling easy installation and uniform appearance. The wide range of finishes and profiles allows architects and designers to achieve modern, elegant facades that are durable and easy to maintain.

Key Benefits of Composite Wall Cladding

- Long-term resistance to UV rays and moisture

- Fire-retardant options for enhanced safety

- Easy cleaning and minimal maintenance

- Customizable textures and colors for unique aesthetics

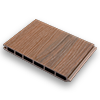

Wood Plastic Composite Panels for Outdoor DIY Projects

Wood plastic composite panels are versatile solutions for outdoor DIY projects, including garden pathways, terraces, fencing, and patio furniture. The unique combination of wood fibers and recycled plastics creates a material that is both lightweight and strong, making it easy to handle during installation without sacrificing durability.

We manufacture panels in various dimensions and finishes to accommodate a wide range of project requirements. Our panels can be cut, drilled, or fastened with standard tools, allowing DIY enthusiasts and contractors to customize designs while ensuring long-term resilience against weather and wear.

Practical Considerations for Composite Panels

- Non-slip surfaces for safety in wet areas

- Resistance to rot, decay, and insect damage

- Lightweight and easy to transport for DIY installations

- Compatibility with modular design systems for creative layouts

Innovations in Material Technology

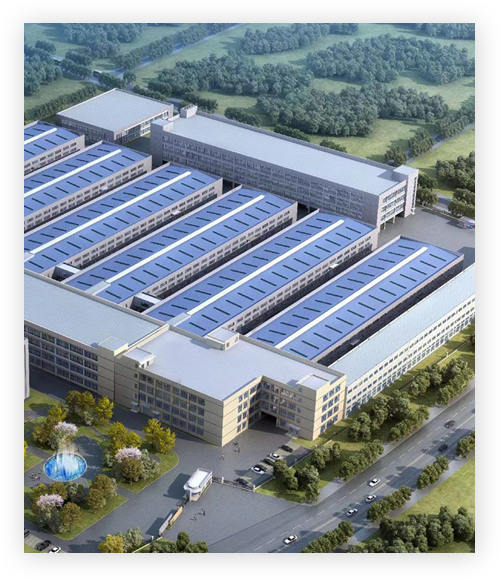

Recent advances in composite technology have improved the structural stability and aesthetic versatility of decking boards, cladding, and panels. UV-stabilized additives and high-density plastics increase longevity while preserving vibrant colors. In our factory, we integrate these innovations across 20 production lines, ensuring each batch meets high performance standards at a competitive price.

Additionally, surface embossing techniques replicate natural wood grain patterns, delivering premium finishes without the maintenance issues associated with traditional timber. This allows architects, builders, and DIY enthusiasts to achieve both elegance and practicality in outdoor spaces.

Sustainable Benefits of Composite Materials

Wood plastic composites are environmentally friendly, utilizing recycled plastics and sustainably sourced wood fibers. This reduces waste and deforestation while providing high-performance alternatives to conventional wood products. Choosing composite materials supports sustainable construction practices and appeals to eco-conscious consumers.

From our perspective, incorporating sustainable composites into projects not only enhances durability and aesthetics but also promotes responsible environmental stewardship. We are proud to offer products that meet both performance and sustainability criteria for global markets.

Installation Efficiency and Customization Options

Ease of installation is a key advantage of composite decking and cladding. Many products feature interlocking systems or hidden fasteners, reducing assembly time and improving finish quality. Our production facility can customize board lengths, thicknesses, and profiles to fit specific project needs, ensuring efficiency for both commercial and residential applications.

Furthermore, we offer a variety of finishes, colors, and textures to match design preferences while maintaining the functional benefits of composite materials. This flexibility allows designers and DIY enthusiasts to achieve distinctive looks without compromising durability.

Conclusion: The Value of Composite Materials in Modern Construction

Composite decking boards, wall cladding, and wood plastic panels represent a convergence of durability, aesthetic appeal, and sustainability. Advanced manufacturing techniques, combined with versatile design options, allow these products to outperform traditional wood in most outdoor applications.

At Huzhou BASO New Materials, we combine experience, technology, and quality control to deliver composite products that meet diverse project requirements. Whether for professional construction or DIY projects, our materials provide long-lasting performance, low maintenance, and elegant finishes, making them a practical choice for international markets.

Español

Español