Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

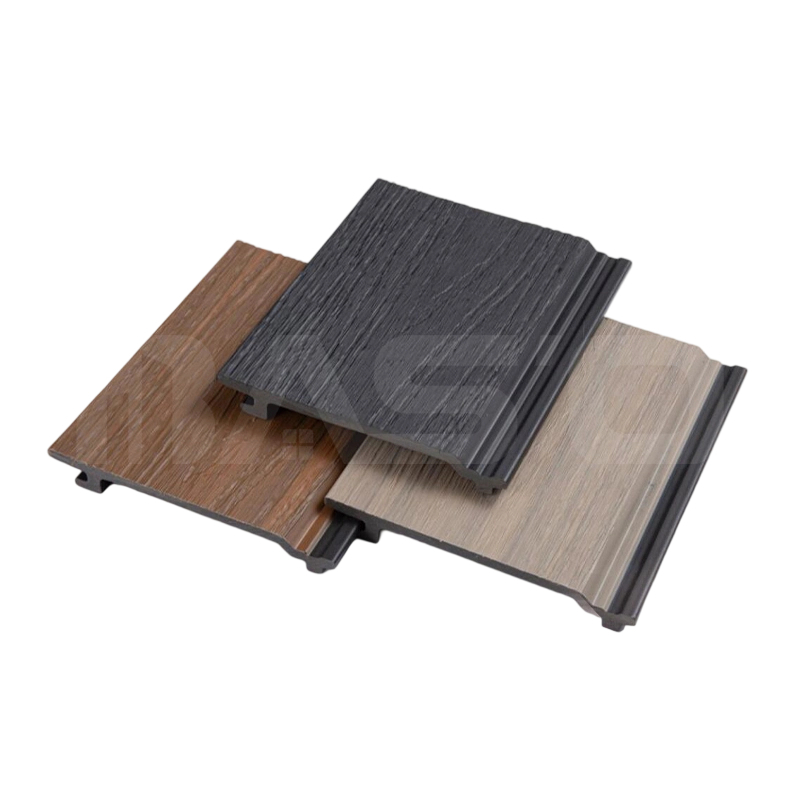

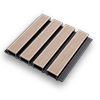

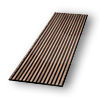

Co-Extrusion Capstock: What Bulk Buyers Should Verify Beyond “UV Resistant” Claims

In co-extrusion wall panels, the protective “capstock” layer is doing most of the long-term work. For bulk procurement, it is more actionable to verify capstock polymer type and capstock thickness consistency than to rely on generic weather-resistance descriptions.

Practical verification points

- Confirm whether the capstock is engineered for outdoor exposure (UV stabilizers, pigment system, and anti-oxidation package). Ask for the formulation category rather than a single additive name.

- Request thickness control data (process records or QC sampling). A stable cap layer helps reduce color shift and chalking over time; inconsistent cap thickness often shows up as uneven gloss or premature fading.

- Check the cap-to-substrate bond method (true co-extrusion vs. post-lamination). True co-extrusion typically provides more reliable interfacial bonding under thermal cycling.

From our side, we treat capstock stability as a purchasing KPI because it directly impacts warranty risk; if you need a dependable, price-competitive supply for volume projects, we can align QC checkpoints to your acceptance criteria.

Color Fastness in Outdoor Cladding: Why Pigment Strategy Matters More Than Shade Cards

Bulk buyers often approve based on shade cards, but outdoor color retention is mainly driven by the pigment system and UV package in the co-extrusion layer. Two panels can match on day one yet diverge after extended exposure.

Procurement-ready questions to ask

- Is the color built with inorganic pigments (typically stronger UV stability) or organic pigments (often brighter but can be less stable depending on chemistry and loading)?

- What is the expected color drift tolerance for the project (ΔE target)? Locking acceptance bands in writing reduces disputes between lots and installation phases.

- How is batch-to-batch color controlled (masterbatch traceability, inline color monitoring, or lab spectro checks)? Traceability is especially important for multi-container orders.

If your project requires multiple shipments over time, it is worth standardizing on a controlled color recipe and referencing a single retained master panel; in our production, we can maintain consistency across large volumes and reorders with lot-based traceability.

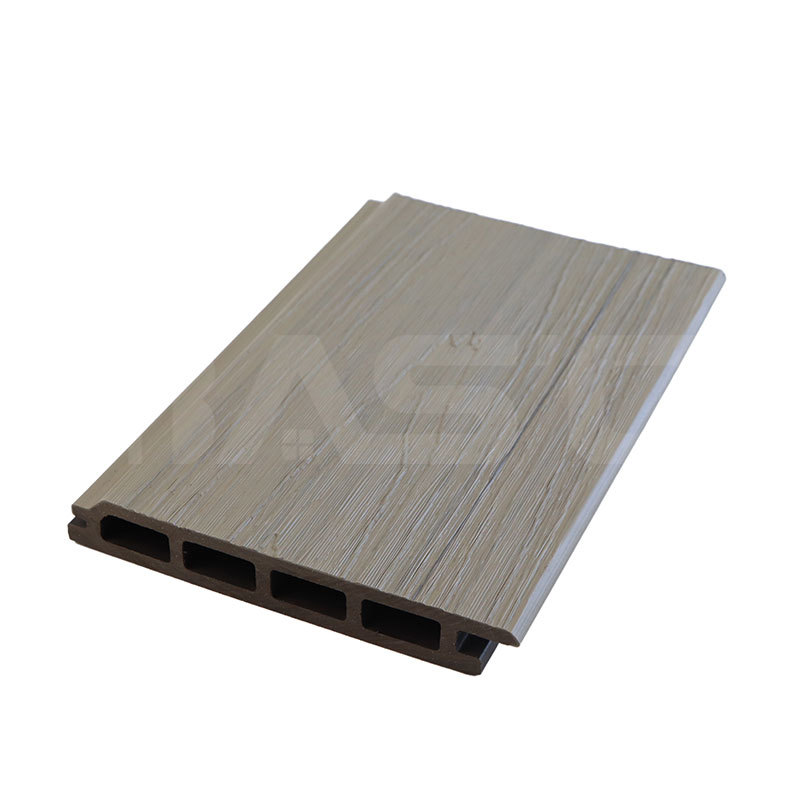

Thermal Expansion Planning: Joint Design and Fixing Methods That Prevent Callbacks

Wood-plastic composite systems expand and contract with temperature changes. The practical risk in exterior walls is not expansion itself, but poor detailing—tight end joints, incorrect fasteners, or insufficient movement gaps.

Constructive detailing considerations

- Specify movement gaps at ends and around penetrations; use trim profiles that allow sliding rather than “locking” the board.

- Prefer fixing systems designed for WPC cladding (clips or slotted holes) where possible; rigid point-fixing can concentrate stress and cause waviness.

- Separate structural requirements from decorative surface alignment; keep a consistent subframe layout to reduce panel telegraphing.

For bulk orders, we recommend confirming the intended substructure and fixing accessories early; we can supply matching profiles and advise on installation-friendly tolerances so your installation teams avoid rework.

Moisture Management: Ventilated Rainscreen Concepts Applied to Co-Extrusion Wall Panels

Even when panels are moisture resistant, exterior wall assemblies still benefit from a rainscreen approach. The goal is to prevent trapped moisture behind the cladding and reduce mold risk in the wall system.

Assembly-level practices that help

- Provide an air gap behind panels with top/bottom ventilation routes; a continuous cavity improves drying after rain events.

- Use flashing and drip edges at terminations to prevent water from being pulled back into the cavity.

- Avoid sealing every edge “airtight”; the objective is controlled drainage and drying, not a moisture trap.

A well-detailed rainscreen reduces long-term service issues, especially in humid or coastal regions; the co-extrusion cap layer is protective, but good wall design is still the cheapest insurance.

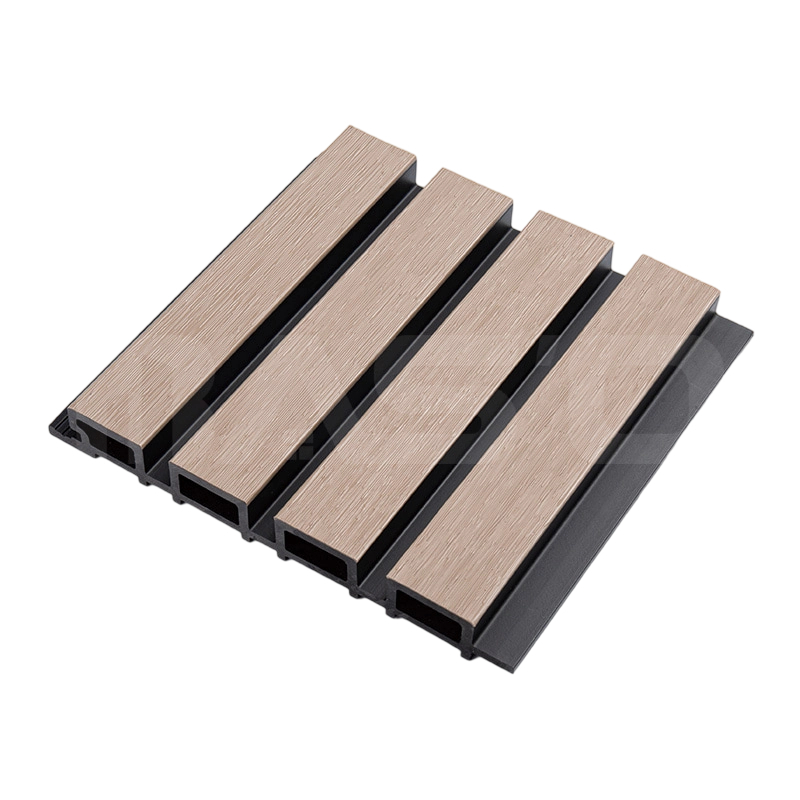

Surface Texture Selection: How Embossing and Brushing Affect Dirt Visibility and Maintenance

Texture is not only decorative—it influences maintenance frequency. Deep wood grain and embossed finishes can mask minor scuffs, while very smooth finishes can show dust patterns and water marks more clearly depending on site conditions.

Practical guidance for project specifications

- High-traffic areas: deeper textures can visually hide micro-scratches; embossed grain often performs well in commercial settings.

- Dusty environments: medium textures can help reduce the appearance of streaking compared to very smooth surfaces.

- Coastal or industrial zones: select textures that are easier to rinse clean; avoid patterns that can trap residue if regular wash-down is expected.

If you share your application scenario (residential façade, retail frontage, industrial perimeter), we typically propose two or three surface options that balance appearance, maintenance, and cost for bulk purchasing.

Scratch, Stain, and Chemical Resistance: Setting Realistic Acceptance Standards for Site Use

Co-extrusion surfaces resist common stains and weathering, but bulk buyers benefit from translating “durable” into measurable site acceptance rules. The key is aligning performance with how the cladding will be handled, cleaned, and exposed during construction.

Recommended acceptance thinking

- Define a cleaning protocol for handover (water + mild detergent) and restrict harsh solvents; construction chemicals should be tested on offcuts first.

- Specify handling requirements (edge protection, storage on flat pallets, avoid dragging). Many “surface defects” are logistics-related, not manufacturing-related.

- Agree on allowable visual variation for textured surfaces; embossed patterns can vary slightly by angle and lighting, which is normal.

For large shipments, we encourage buyers to standardize inspection conditions (viewing distance, lighting, and acceptance thresholds). This reduces unnecessary claims and keeps delivery schedules stable—something we prioritize in volume supply.

Fire and Compliance Considerations: How to Approach Project Requirements Without Over-Specifying

Exterior cladding requirements vary widely by jurisdiction and building type. For bulk procurement, the most practical approach is to align on the required system performance level early and avoid specifying unnecessary features that increase cost without improving compliance.

Actionable steps for buyers

- Confirm which standard or classification the project references (local building code, façade classification, or project-specific testing requirement).

- Clarify whether testing applies to the board alone or to the full wall assembly (including substructure, cavity barriers, and insulation).

- Document any restrictions on surface treatments, adhesives, or accessory profiles that might affect compliance.

If you provide the project’s compliance target, we can match suitable configurations and supporting documentation for bulk supply. The key outcome is meeting the requirement precisely—no more and no less.

What to Include in a Bulk Purchase Specification Sheet for Co-Extrusion Wall Panels

A clear spec sheet prevents the most common bulk-order issues: mixed surface texture, color drift across batches, dimensional mismatches, and accessory incompatibility. Below is a practical checklist that reduces ambiguity between procurement, factory, and installers.

| Spec Item | What to Define | Why It Matters |

|---|---|---|

| Panel profile | Width, thickness, rib design, edge type | Ensures accessory fit and consistent appearance |

| Capstock surface | Texture (embossed/brushed), gloss band, color ID | Controls batch consistency and cleaning behavior |

| Dimensional tolerances | Length tolerance, straightness, squareness | Reduces installation delays and material waste |

| Accessory system | Start/finish trims, corners, clips, screws | Avoids site improvisation and visual defects |

| Packing & labeling | Lot labels, pallet layout, protection film needs | Supports traceability and reduces transit damage |

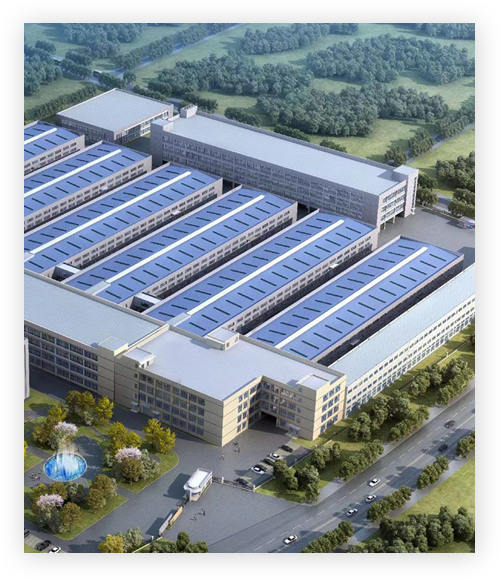

We typically align this checklist with your inspection workflow (incoming QC, on-site checks, and installation method). With over 20 production lines, we can support large volumes while keeping spec compliance and cost control aligned.

Mold, Mildew, and Biofouling: What “Resistant” Means in Real Outdoor Conditions

Co-Extrusion Wall Panel surfaces reduce moisture absorption and limit nutrient availability on the surface, which helps inhibit mold and mildew. However, in shaded and humid locations, biofouling can still develop on any exterior surface if dust and organic debris accumulate.

Maintenance practices that materially reduce issues

- Specify periodic rinsing in shaded façades, especially under eaves and near landscaping irrigation overspray.

- Design for drainage: avoid horizontal ledges where debris can sit; add drip details where water can cling and stagnate.

- If cleaning agents are used, require compatibility testing on sample pieces; gentle cleaners preserve surface appearance.

In procurement terms, “mold resistance” is best treated as a combination of material choice and façade detailing. When both are managed, long-term appearance stays stable with minimal upkeep.

Customization for Large Projects: Mold Strategy That Balances Uniqueness and Cost

Custom profiles can differentiate a façade, but the cost-efficiency depends on how you approach molds and SKUs. Bulk buyers get the best economics when customization is tied to repeatable modules rather than one-off dimensions.

Practical approaches that reduce risk

- Standardize visible face widths while customizing only edge geometry (clip channel, tongue-and-groove shape). This preserves design intent with fewer new variables.

- Limit the number of colors/textures per elevation to avoid lot mixing and simplify reorders.

- Approve a “golden sample” plus a signed drawing; treat it as the controlling reference for mass production and future replenishment.

Our team supports custom molds for different profiles, and we focus on making the customization manufacturable at scale so you keep both timelines and budgets predictable—that is where bulk buyers win.

Español

Español