Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

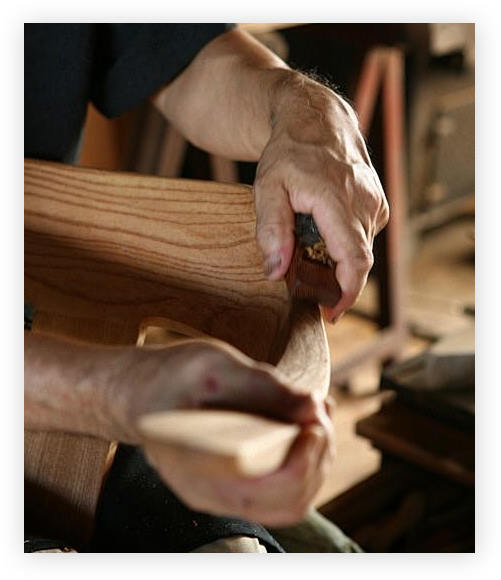

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

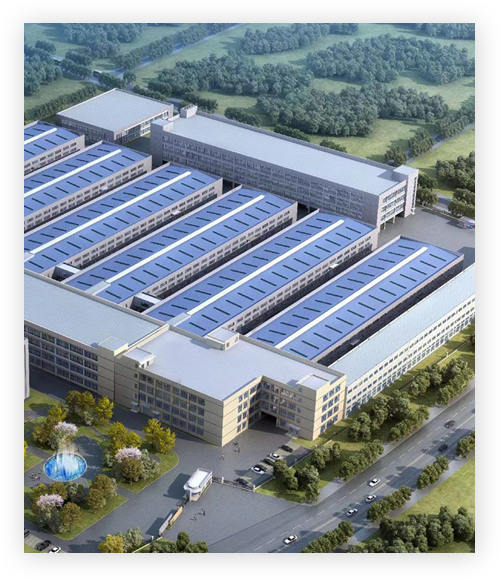

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

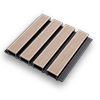

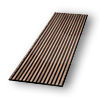

How to Specify WPC Wall Panels for Bulk Procurement

Bulk orders go smoother when you specify performance targets instead of only visual patterns. For Classic WPC wall panels, focus on how the panel will behave in the real environment (humidity swings, cleaning frequency, temperature range) and translate that into measurable acceptance criteria. In our projects, clear specs reduce rework and shorten delivery cycles—the fastest orders are the ones with the least ambiguity.

Practical parameters to include on your PO

- Application: indoor / semi-outdoor / outdoor; wall / ceiling; wet zone or dry zone.

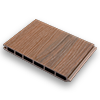

- Profile & dimensions: thickness, width, length, and whether you need hollow or solid structure.

- Surface finish: wood grain, brushed, matte/gloss level, and directionality (important for alignment).

- Color consistency rule: define an acceptable delta between batches and whether you will mix cartons during installation.

- Installation system: clip type, screw spacing guidance, edge trims, and corner solutions (avoid “field improvisation”).

- Packaging & labeling: carton quantity, pallet standard, barcode/lot coding for traceability.

If you share your end-use scenario, I can help you map it into a clean, factory-friendly spec sheet. That is often the difference between “acceptable” and consistently excellent deliveries.

Understanding Performance Tradeoffs: Hollow vs. Solid WPC Panel Profiles

The internal structure of a WPC panel affects rigidity, fastener holding, acoustics, and cost. A hollow profile is not “lower grade” by default—its engineering can be ideal when weight and logistics matter. Solid profiles are often preferred where impact resistance and edge finishing are critical. The key is matching procurement to installation realities.

| Factor | Hollow Profile | Solid Profile |

|---|---|---|

| Weight & shipping | Lower weight; easier handling on site | Heavier; higher logistics cost |

| Rigidity on imperfect walls | Good if subframe is level | More forgiving under local stress |

| Impact resistance | Moderate; depends on wall backing | Higher; better for high-traffic zones |

| Fastener holding | Best with clips + correct spacing | Stronger edge and screw holding |

| Cost efficiency | Often more economical per installed m² | Higher raw material consumption |

For bulk buyers, the smartest approach is to standardize one profile family across multiple projects and only switch when the site conditions demand it. Our production capacity supports stable, repeatable profiles—so your procurement remains predictable even at scale.

Moisture Management and Substrate Prep in Wet or Semi-Outdoor Areas

WPC cladding is well known for waterproof and anti-mildew behavior, but the hidden failure mode in wet areas is not the panel—it is trapped moisture behind the system. If you specify WPC wall panels for bathrooms, pool surrounds, basements, or semi-outdoor corridors, procurement should include a moisture strategy.

What to demand from the installation design

- Ventilation gap or batten system to prevent “sealed cavity” condensation.

- Moisture-resistant backer board or treated substrate; avoid installing directly over unstable, damp plaster.

- Compatible sealant at perimeter transitions (panel-to-tile, panel-to-aluminum, panel-to-glass).

- Defined drainage path at the bottom edge; do not trap water at skirting lines.

When buyers include these requirements up front, the result is a finish that stays clean and stable with minimal maintenance—exactly what WPC panel systems are meant to deliver.

Color Consistency Across Lots: Managing “Batch Drift” in Large Projects

For bulk purchases, the most visible quality issue is color difference between production lots—especially with wood-grain and brushed textures that catch light differently. Even with tight process control, minor variation can occur because polymers, wood powder, and pigments respond to temperature and pressure changes during extrusion.

Procurement practices that reduce risk

- Order full-project quantity with a single planned production run where possible; one run is better than three corrections.

- Require lot codes on cartons and pallets so site teams can blend cartons intentionally.

- Approve both “daylight” and “warm indoor” visual samples; metamerism can surprise buyers.

- Define a standard sample retention rule (factory keeps a sealed reference panel for future matching).

Because we run multiple lines, we can plan production to keep the same mold/finish parameters consistent throughout a large order. That planning is a small step that protects a very large installation.

Thermal Expansion and Joint Design for WPC Cladding Systems

WPC contains polymer content, so it expands and contracts more than natural wood in most climates. The panel itself is durable, but poor joint design can create buckling, edge lift, or audible “clicking.” In bulk projects, most failures traced to WPC wall panels are actually installation tolerance failures, not material failures.

Design considerations to insist on before purchasing

- Expansion allowance at ends and around penetrations (outlets, light boxes, pipes).

- Clip system compatibility: clip spacing should match profile stiffness and expected temperature swing.

- Avoid “hard locks” at corners; use corner trims that allow micro-movement.

- Store panels flat and acclimate near the installation area to reduce post-install movement.

If you standardize the joint rule across projects, you reduce installer variability. We can supply matching trims and consistent profiles so the movement strategy remains uniform from tender to handover.

Surface Texture Selection: Wood Grain vs. Brushed for Cleaning and Wear

Texture is not only decoration; it changes how the surface hides scratches, retains dust, and responds to cleaning chemicals. For commercial interiors (lobbies, malls, offices), buyers should evaluate textures as part of lifecycle cost, not just sample-board appearance.

| Texture | Strength in Use | Watch-outs |

|---|---|---|

| Wood grain | Hides minor scuffs; premium natural look | Deep grooves can retain dust if not wiped properly |

| Brushed | Modern style; easier uniform cleaning strokes | Directional sheen may reveal misalignment if installers rotate boards |

| Fine matte | Best for high-frequency cleaning | May show oily fingerprints in some lighting |

For bulk buyers, the most practical approach is to choose one “core” texture for 80% of projects, then reserve specialty textures for feature walls. This keeps procurement simple and makes your warehouse inventory more efficient.

Fire and Compliance Considerations Buyers Commonly Miss

Many buyers focus on waterproof performance and forget that wall lining materials often require fire-related documentation depending on jurisdiction, occupancy type, and installation location (egress routes, hotel corridors, public venues). WPC wall panels can be part of a compliant system, but bulk procurement should treat compliance as a system question, not a single-material claim.

What to request from suppliers and installers

- Test documentation that matches your market (standard and lab name should be clearly stated).

- Clarity on whether the rating applies to the panel alone or the complete wall assembly (substrate + adhesive/fasteners + panel).

- Installation method statement: adhesives and insulation can change results in real builds.

- Lot traceability: keep a record of batch/lot numbers tied to test reports when projects are audited.

When compliance is handled early, your procurement becomes defensible and repeatable. We are used to supporting bulk buyers with documentation packages aligned to project needs, and we keep production lots traceable for professional delivery.

Mold Customization Strategy: When a New Profile Actually Pays Off

Custom molds can differentiate your product line or fit a unique installation constraint, but they only create value when the volume and lifecycle justify the tooling. Experienced bulk buyers treat mold development like a small capex project: define the objective, validate the profile engineering, and lock in a volume plan.

Decision criteria used in professional sourcing

- Functional need: solving a real installation issue (coverage width, concealed fasteners, corner integration).

- Aesthetic signature: unique shadow line or texture direction that your competitors cannot match easily.

- Supply chain benefit: standardizing trims and reducing SKU complexity across regions.

- Volume threshold: a planned MOQ that makes tooling cost negligible per m² over time.

Because we operate with over 20 production lines and support different molds, we can help you evaluate whether a custom WPC panel profile is a smart investment or an unnecessary complication. In my experience, the best custom profiles reduce labor on site, not just look different.

Quality Control Signals to Check on Arrival (Fast, Practical, Non-Lab Methods)

Bulk buyers often want “QC,” but what you really need is a quick receiving inspection that flags problems before installation. WPC wall panels are typically stable, yet damage can occur from handling, storage, or incorrect packing orientation. A 15-minute check per pallet can prevent expensive callbacks.

Receiving inspection checklist

- Check carton labels: model, color code, lot number, and quantity match PO.

- Visual straightness: sight down the length for bowing; isolate any suspect cartons before mixing.

- Locking/clip fit: test-fit two panels from different cartons to confirm consistent engagement.

- Surface inspection under angled light: confirm uniform texture direction and no compression marks.

- Packaging integrity: crushed corners and strap marks often indicate transit stress—document immediately.

If you want, we can align your acceptance checklist with how our factory packages and ships, so your warehouse team can confirm compliance quickly and confidently—this is one of the simplest ways to protect margin on large orders.

Installation Efficiency: Hidden Costs That WPC Panel Systems Can Reduce

Bulk buyers evaluate unit price per panel, but the true cost is installed cost per m². WPC cladding often wins because it can reduce skilled labor time, surface prep intensity, and rework compared with traditional wood wallboards that demand ongoing treatment. The best procurement strategy is to buy the system that minimizes site variability.

Where the savings typically come from

- Reduced finishing steps: no painting or varnishing cycles on site.

- Lower maintenance planning: waterproof and mildew-resistant behavior reduces operational burden.

- Cleaner cut-and-fit: stable profiles simplify alignment of long runs and corners.

- Predictable accessories: matching trims and clips reduce last-minute sourcing and substitutions.

I design our recommendations around total installed performance, not just a sample-board impression. If you are sourcing at volume, consistency is the product—and that is exactly what we build our manufacturing around.

Español

Español