Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

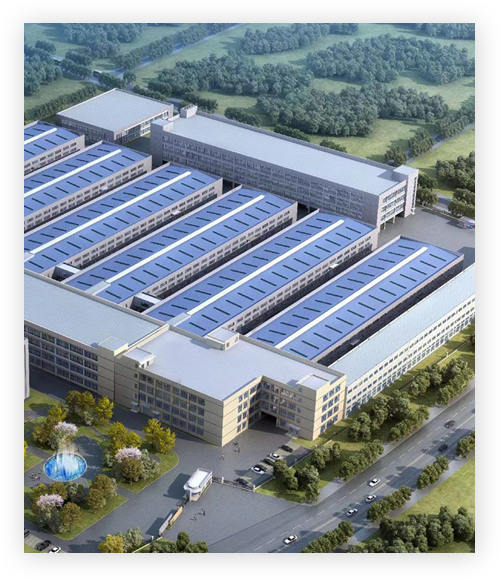

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

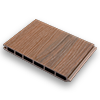

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

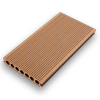

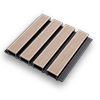

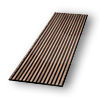

How 3D Deep Embossing Changes Slip Behavior in Wet Zones

Bulk buyers often evaluate “anti-slip” using only surface roughness, but deep embossing affects traction in two ways: micro-texture (fine grain) and macro-channels (deeper ridges). On rainy decks, the macro-channels help break the water film so the shoe sole can contact the surface more effectively. The practical takeaway is that deep grain is not only aesthetic; it can contribute to more stable walking behavior in splash-prone areas.

Procurement tip for high-traffic projects

- Prioritize deep embossed profiles for pool surrounds, coastal decks, café terraces, and ramps where a thin water layer is common.

- If you must spec smooth boards for design reasons, isolate them to covered zones and keep embossed boards at entrances and wet transitions.

- Ask for a sample panel and do a simple on-site wet shoe test; the difference is usually noticeable when the grain is truly deep.

When we produce 3D embossed WPC decking, we focus on consistent grain depth across batches, because inconsistent embossing can create inconsistent grip—a common pain point on large-volume orders.

UV Stability: What Buyers Should Verify Beyond “Anti-UV” Claims

Outdoor composites age mainly through UV-driven polymer chain changes and pigment degradation. “Anti-UV” is not a single additive; it is a system involving stabilizers, pigment quality, and correct dispersion. For bulk purchasing, the practical risk is color shift and surface chalking, especially on south-facing installations or high-altitude regions.

What to request during supplier evaluation

- Accelerated weathering references: ask what method they use internally and what pass/fail criteria they follow (even if you don’t need the full report).

- Pigment strategy: carbon black for dark tones is typically strong in UV shielding; for light tones, stabilizer selection matters more.

- Batch control: confirm whether the supplier controls color by recipe lock and lot tracking; this is essential if you will reorder months later.

From a buying perspective, repeatability across batches is often more valuable than an aggressive “zero fading” marketing promise. In our factory, we treat lot consistency as a core KPI because it reduces rework and complaint costs for long-running projects.

Wear Resistance: Why Emboss Depth Must Match Foot Traffic

Wear on 3D embossed decking is not only “material hardness.” Deep grain creates higher peaks and valleys; in heavy foot traffic, the peaks see more abrasion. If the emboss is shallow, you lose texture quickly; if it is truly deep and the wear layer is engineered properly, the surface keeps its wood-like look longer.

How to spec for different usage scenarios

| Use Area | Traffic Level | Recommended Texture Approach | Buyer Focus |

|---|---|---|---|

| Residential patio | Medium | Deep embossed for aesthetics + grip | Color stability and comfort |

| Restaurant terrace | High | Deep embossed with robust wear design | Long-term texture retention |

| Poolside / coastal | Medium-High | Deep embossed emphasizing drainage channels | Slip behavior + mold control |

| Public walkway | Very High | Deep embossed only if abrasion performance is verified | Maintenance planning |

If your project includes mixed-use zones, a smart approach is to keep the same color but change the texture profile by area; it preserves design consistency while optimizing durability.

Waterproof vs. Water Management: Details That Prevent Callbacks

WPC boards are generally resistant to water, but many failures blamed on “waterproofing” actually come from water management: trapped moisture, poor ventilation, and incorrect drainage slopes. Deep embossed surfaces can mask minor water spots better than flat surfaces, but substructure design remains the deciding factor for long-term performance.

Practical build details bulk buyers should standardize

- Ensure airflow beneath boards; blocked ventilation is a leading cause of odor and mold complaints even with mildew-resistant materials.

- Specify drainage slope and keep gaps consistent; uneven gaps create water traps and visible alignment issues.

- Use compatible fasteners and avoid galvanic corrosion in coastal zones.

For large projects, we often recommend locking installation details into a single method statement so every crew executes the same spacing, slope, and fastening rules—this is where bulk buyers win on total cost.

Mold, Mildew, and Biofouling: What Actually Works Outdoors

Outdoor “mold resistance” is rarely about the board being immune; it is about how easily organic matter can be removed and how quickly surfaces dry. Deep embossed grain can hold more dust if neglected, but it also hides minor staining better. The best control strategy combines material selection with cleaning rhythm and jobsite rules.

Site rules that reduce complaints

- Stop fertilizer, soil, and sawdust from sitting on the deck surface during landscaping; these feed mildew.

- Plan a first clean after installation; early staining is often construction residue, not product failure.

- In shaded zones, schedule periodic rinsing; drying time is the real enemy in biofouling control.

If you manage multiple sites, a simple cleaning SOP reduces disputes dramatically; our team can align product selection to your regional climate and maintenance capability without over-complicating your purchasing process.

Dimensional Stability: Understanding Expansion Gaps for WPC

WPC expands and contracts with temperature changes. Bulk buyers should treat spacing as a specification item, not an installer preference. Deep embossed surfaces do not change the thermal behavior, but they can make minor alignment errors more visible at certain lighting angles, so controlled spacing and straight joist lines matter even more for premium finishes.

Where expansion issues show up first

- Long continuous runs without breaks: cumulative movement increases board end stress.

- Dark colors in full sun: higher surface temperature drives more movement.

- Perimeter constraints against walls or posts: insufficient gaps cause buckling or squeaks.

A practical buying strategy is to standardize a gap rule by climate band; consistent installation tolerances protect you more than any single “premium” feature.

Fasteners and Substructure: Avoiding Squeaks, Pop-ups, and Edge Damage

In field failures, the board is often blamed, but the real root cause is fastening mismatch or joist irregularity. Deep embossed WPC decking typically targets a premium visual standard, so fastening quality is more noticeable. The board surface may look “high-end wood,” but if the substructure is uneven, you will still see lipping and feel bounce.

Bulk buyer checklist for system compatibility

| Component | Common Risk | Control Method |

|---|---|---|

| Hidden clips | Board walk / squeak | Use clips matched to board profile; keep screw torque consistent |

| Joists | Lipping and bounce | Flatness control and correct spacing |

| Edge finishing | Chipping / visible gaps | Standardize trim profiles and corner details |

We operate with multiple production lines and stable tooling capability, so if your project requires a specific clip groove or edge profile, we can support mold customization while keeping supply continuity for repeat orders.

Color Matching Across Containers: Reducing Reorder Risk

For bulk buyers, the biggest practical color problem is not “fading over years,” but mismatch between early shipments and later replenishment. Pigment dispersion, process temperature, and recipe drift can create subtle tone differences that become obvious after installation—especially on large open decks.

Controls you can require in purchase terms

- Define color tolerance handling: require the supplier to ship by batch/lot and label cartons accordingly.

- Reserve reorder material: if schedules allow, buy a small contingency quantity from the same batch for future repairs.

- Use “mixing rule” on site: installers should mix boards from multiple cartons to reduce any micro-variation appearance.

In my experience supporting bulk buyers, lot discipline is one of the cheapest ways to prevent expensive change orders, and it is easy to formalize in your PO and packing requirements.

Mold Customization: When Custom Profiles Are Worth It

Custom molds are not only for aesthetics. They can standardize installation systems, improve edge finishing, and reduce accessory complexity. For large purchasers, the decision should be based on how many projects will reuse the same profile, and whether a unique profile improves install speed or reduces after-sales service.

Situations where customization brings measurable value

- You manage chain-store rollouts and want the same board system across regions.

- You want a proprietary surface/edge to reduce direct price comparison in tenders.

- You need a specific groove/clip interface to match an existing substructure standard.

Because BASO has extensive production capacity and tooling experience, we can support customized molds while maintaining stable output—my goal is to help you scale without compromising delivery reliability or unit economics.

Español

Español