Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

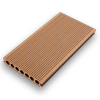

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

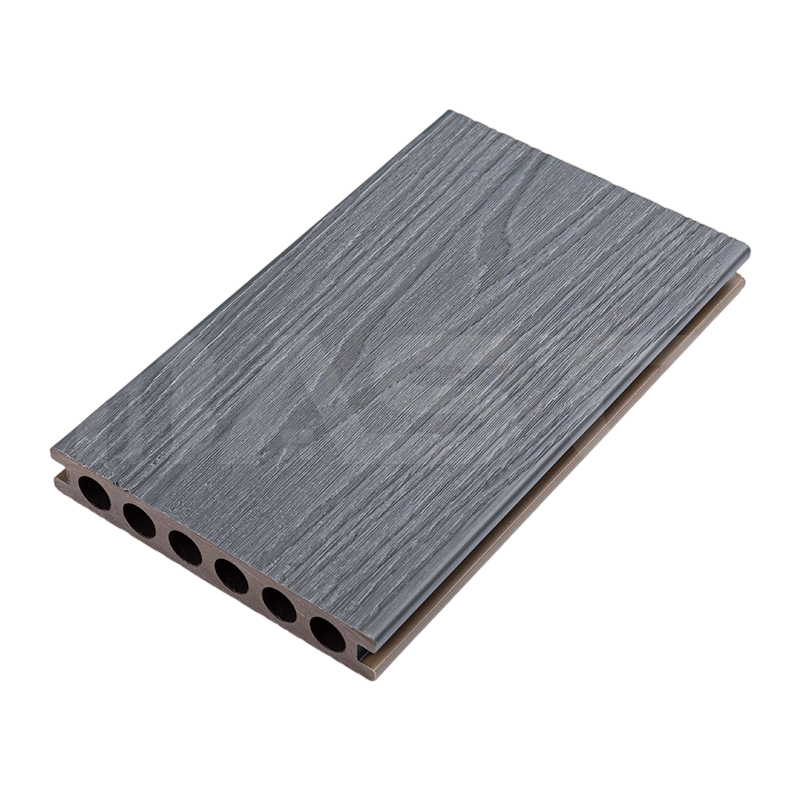

Co-Extrusion Cap Layer: What You Can Specify (Not Just “Better Protection”)

For bulk procurement, “co-extruded” alone is not a spec. What matters is the cap’s polymer recipe, the cap/core bonding stability, and the surface engineering (emboss depth and matte control). When the cap layer is formulated correctly, it forms a durable barrier against UV, moisture, and staining agents—this is the part that keeps the deck looking consistent across large projects.

In practice, a high-performing cap layer should deliver color stability, stain release, and scratch masking under real foot traffic and outdoor exposure. In our own production, we focus on process stability across long runs, because batch-to-batch consistency is where many large orders win or lose.

- Ask for cap-layer material disclosure (polymer family + UV package approach) rather than generic “UV resistant” claims.

- Confirm whether the cap is engineered for stain release (low surface energy) versus just hardness.

- For large sites, request a production plan that controls color drift between lots.

Wear, Scratch, and “Real-World” Expectations on Commercial Installs

Co-extrusion improves surface durability, but bulk buyers should align wear expectations with the usage scenario: cafes, rooftop events, pool perimeters, and high-heel traffic each stress the surface differently. A harder cap can reduce gouging, while a well-designed texture can visually hide micro-scratches.

Practical guidance for specifying surface performance

- Choose deeper embossing for public walkways to help mask abrasion over time.

- For hospitality projects, prioritize stain release and cleanability over ultra-high gloss, which can highlight scuffs.

- For rooftop decks, specify heat-management and color stability together; dark boards can run hotter even with good UV control.

If you share your application scenario, I can usually match a surface texture and cap formulation approach that reduces maintenance complaints—small decisions here prevent costly post-install callbacks.

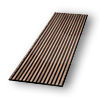

Color Consistency in Large Orders: How to Control Shade Across Lots

On multi-container orders, the most common bulk issue is not structural failure—it’s shade variation across production dates. Co Extruded Composite Decking can maintain color well outdoors, but large projects also need controlled color matching from the start.

What to request before mass production

- A signed “golden sample” that becomes the internal color reference for the run.

- A lot plan: keep one project within the same pigment lot when possible.

- Packaging labels tied to production batches to simplify on-site sorting.

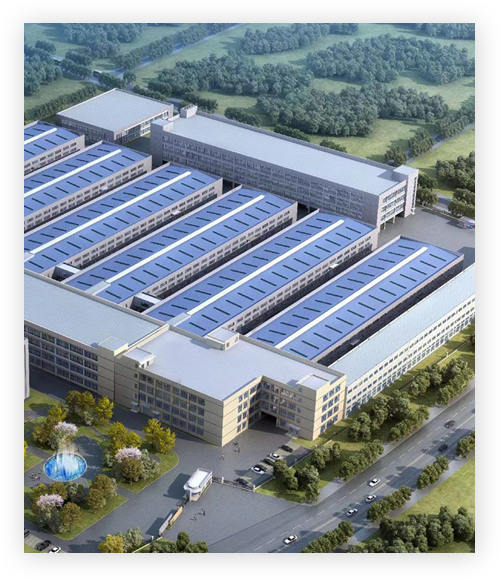

With our scale (multiple lines running in parallel), we pay attention to run sequencing so bulk buyers can receive stable shade across pallets—this is where factory discipline matters more than marketing language.

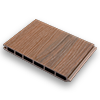

Slip Performance: Texture, Drainage, and Site-Specific Risk

Slip behavior is influenced as much by surface geometry and drainage design as by the material itself. A co-extruded cap layer helps resist algae and staining, but wet-slip risk still depends on how water evacuates and how the micro-texture interacts with footwear.

Specification levers bulk buyers can actually control

- Prefer directional grooves or brushed textures in wet zones to promote channeling and grip.

- Match board orientation and joist layout to drainage flow; poor drainage can negate a good surface.

- In shaded, humid areas, select a cap design optimized for mildew resistance and faster clean release.

Thermal Movement and Gapping: Planning the Install for Climate Range

Composite systems expand and contract with temperature changes. Co-Extrusion Decking improves surface stability against weathering, but thermal movement still needs correct gapping and fastening choices—especially for long runs and perimeter constraints.

| Design / Install Factor | What to Decide Up Front | Why It Matters |

|---|---|---|

| Board run length | Max continuous length before breaks / transitions | Reduces visual stress lines and crowding at walls |

| Perimeter constraints | Clearance at edges, posts, and thresholds | Prevents buckling in heat cycles |

| Fastening system | Hidden clips vs face screws; clip spacing | Controls movement behavior and finish uniformity |

| Ventilation under deck | Minimum airflow clearance and drainage slope | Improves drying, reduces odor and mildew risk |

For large orders, we can align board length, clip system compatibility, and accessory fit so crews install faster with fewer site adjustments—this is one reason bulk buyers prefer a factory that can execute reliably at scale.

Stain Resistance: What It Covers (and What Still Needs Maintenance Planning)

A co-extruded cap layer can dramatically reduce absorption of common contaminants like oil, sauces, and beverage spills. The key is that the cap is designed for low absorption and easy wipe-off, so stains do not migrate into the core as easily as traditional WPC surfaces.

Operational best practices for property managers

- Define a spill response SOP for oil/grease zones; quick wipe-down improves outcomes even on stain-resistant caps.

- Avoid aggressive solvents unless approved; use neutral cleaners for routine washing.

- For food & beverage venues, select textures that balance cleanability with traction.

If you tell me the site type (restaurant terrace, poolside, marina), I can recommend a surface option that prioritizes stain release without sacrificing appearance—minimal fuss for your maintenance team.

Mold, Mildew, and Moisture: Design Choices That Reduce Complaints

Co-extrusion caps are built to resist moisture ingress and surface contamination, but mildew still tends to appear when organic debris sits on the deck in shaded, damp conditions. Bulk buyers can reduce service calls by combining material selection with drainage and cleaning planning.

- Specify board profiles and under-deck clearance that promote airflow and faster drying.

- Plan debris management (leaf seasons, nearby landscaping) as part of the maintenance schedule.

- In coastal or high-humidity zones, prioritize cap formulations designed for weather resistance and surface clean release.

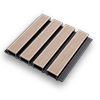

Texture and Aesthetics: Matching “Wood Look” Across Accessories and Edges

Bulk projects rarely fail on the field boards—they fail on finishing details: fascia, edge trims, stair nosing, and transitions. Co-extrusion offers rich textures (wood grain, brushed, stone-like patterns), but visual success depends on a coordinated system approach.

How to keep the finish premium at scale

- Lock accessory SKUs early to avoid mismatched gloss/emboss between shipments.

- Use fascia and edging solutions that share the same cap-layer tone family for a unified perimeter look.

- If you want the most “natural” appearance, specify matte textures and deeper grain to reduce plastic-like sheen.

We support customized molds for different textures and profiles, which helps bulk buyers standardize a unique look across multiple sites while still controlling cost.

Procurement Checklist: What to Lock in Before You Place a Container Order

When you are buying Co-Extrusion WPC Decking in bulk, the best outcomes come from locking “execution details” early. This reduces rework, delays, and site-side improvisation.

- Board profile and dimensions (including tolerances) aligned with your substructure plan.

- Surface option choice (grain depth, brushed vs wood grain) aligned with traffic and cleaning needs.

- Color reference sample + batch control plan to maintain consistency across deliveries.

- Accessory system: fascia, corner trims, stair nosing, clips, and matching fasteners.

- Packaging and labeling requirements for easier site distribution and reduced labor time.

As a manufacturer with over 20 production lines, we can support stable lead times and multi-SKU container planning—bulk buyers typically appreciate how much smoother the logistics become when production and packaging are coordinated from day one.

Español

Español