Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

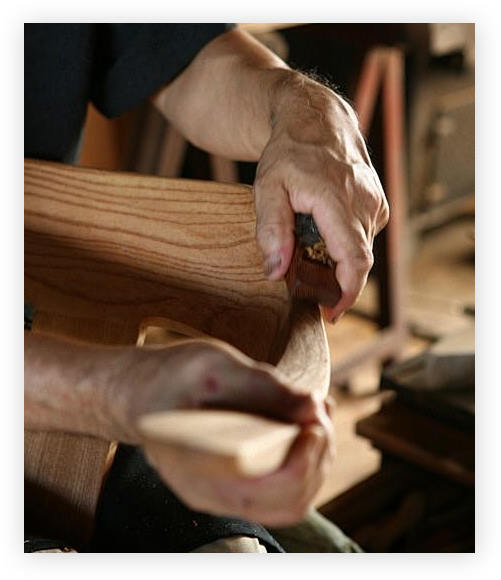

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

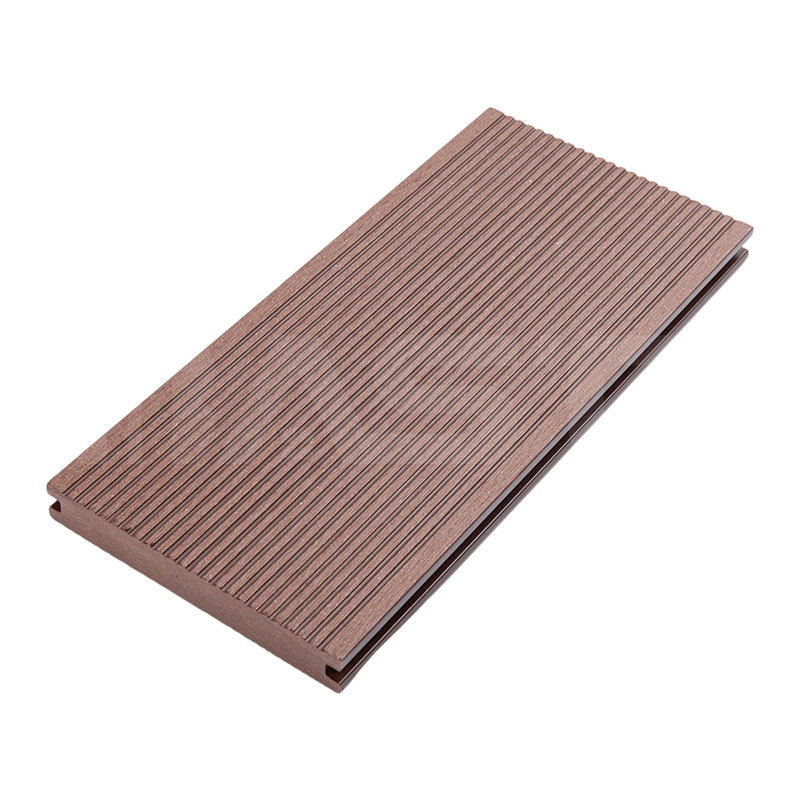

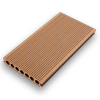

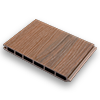

Advantages of Solid Core Composite Decking

Solid composite decking is engineered with a dense, uniform structure that provides maximum strength and stability. Unlike hollow boards, solid core composite deck boards resist bending, warping, and twisting, making them ideal for high-traffic areas and heavy outdoor furniture. The dense structure also allows for superior screw retention, which is critical for long-term stability of the deck surface.

The solid design enhances thermal stability, minimizing expansion and contraction caused by temperature changes. Solid composite boards are often coated with UV-resistant layers, preventing discoloration and surface cracking even in prolonged sunlight exposure. This makes solid composite decking a practical choice for both residential terraces and commercial outdoor spaces.

- Provides excellent load-bearing capacity for heavy furniture and outdoor equipment.

- Resists moisture infiltration, reducing risk of mold, mildew, and rot.

- Long lifespan with minimal maintenance compared to natural wood decks.

- Can be machined, cut, or routed without affecting structural integrity.

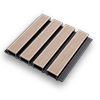

Material Composition and Surface Finishes

Solid core composite deck boards are typically composed of a blend of wood fibers and thermoplastics. The ratio of wood to plastic influences mechanical strength, water resistance, and surface texture. Advanced manufacturing processes allow for embossed or textured finishes that replicate natural wood grain while maintaining a non-slip surface.

| Composition | Key Properties | Recommended Use |

|---|---|---|

| 50% wood fiber / 50% plastic | Balanced aesthetics and durability, moderate water resistance | Residential decks and patios |

| 40% wood fiber / 60% plastic | Enhanced weather resistance, low maintenance, smooth surface | High-traffic commercial spaces |

| 60% wood fiber / 40% plastic | Natural wood feel, moderate durability, more textured finish | Residential terraces with aesthetic emphasis |

Selecting the appropriate composition ensures the deck achieves the desired balance between visual appeal, performance, and longevity.

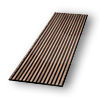

Installation Practices for Solid Composite Deck Boards

Solid composite deck boards require precise installation to maximize durability. Unlike hollow boards, they can be fastened with traditional screws or hidden deck clips, but care must be taken to maintain consistent spacing to allow thermal expansion and contraction.

- Ensure joists are level and spaced according to board width to prevent sagging.

- Use corrosion-resistant screws or fasteners designed for composite materials to avoid staining or surface damage.

- Leave proper expansion gaps at board ends and edges to accommodate temperature-induced movement.

- Pre-drill when working with high-density boards to prevent splitting during fastening.

Maintenance and Long-Term Care

Although solid composite decking is low maintenance, periodic care ensures maximum lifespan. Boards should be cleaned of debris, leaves, and dirt to prevent mold and mildew accumulation. Light pressure washing or gentle scrubbing with mild detergents can remove stains and restore surface appearance without damaging the deck.

- Inspect fasteners annually to ensure boards remain securely attached.

- Remove surface stains promptly to avoid long-term discoloration.

- Apply UV-protective coatings if boards are exposed to direct sunlight for extended periods.

- Maintain drainage around the deck perimeter to prevent standing water, which could affect board edges over time.

Properly installed and maintained solid core composite decking can provide reliable performance, aesthetic appeal, and structural integrity for over 20 years, making it a worthwhile investment for residential and commercial applications.

Español

Español