Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

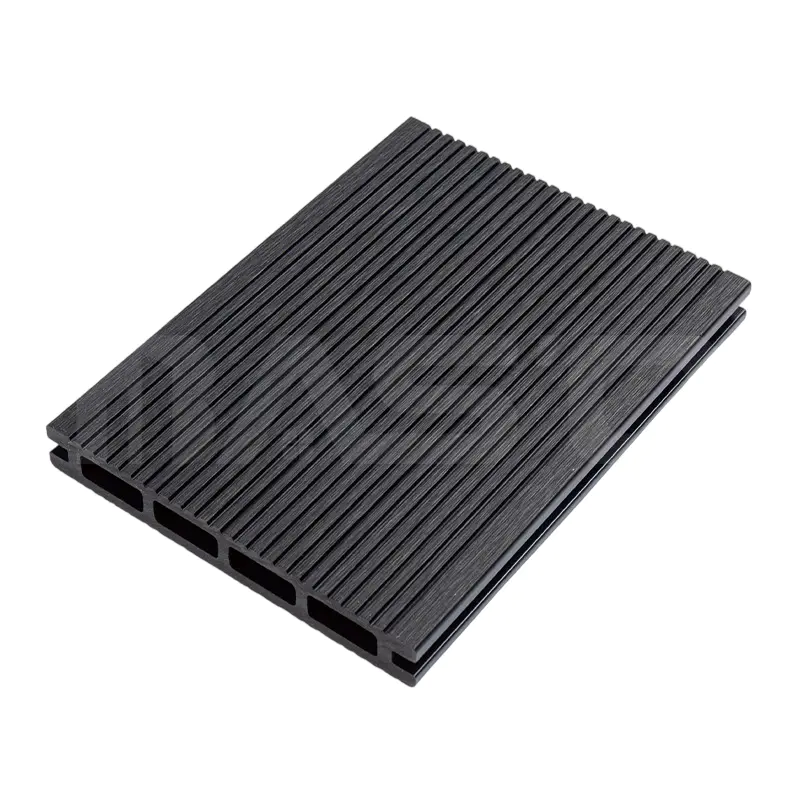

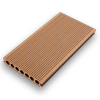

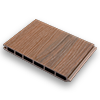

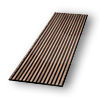

Structural Benefits of Hollow Decking Boards

Hollow decking boards are engineered with internal cavities that reduce overall weight while maintaining structural strength. This design allows for easier handling and faster installation compared to solid boards. The hollow core also improves dimensional stability, reducing the risk of warping, cracking, or swelling caused by environmental changes.

In addition to structural advantages, hollow composite decking allows for efficient drainage. Water can flow freely through the cavities, preventing pooling on the deck surface and reducing the likelihood of mold or algae growth. This is particularly valuable in outdoor environments with frequent rain or humidity fluctuations.

- Lightweight boards reduce the load on supporting joists and substructures.

- Hollow cores provide insulation, keeping the deck surface cooler under sunlight.

- Internal cavities can be designed to enhance sound absorption, reducing impact noise on the deck.

- Hollow boards are easier to cut and customize for complex layouts without heavy machinery.

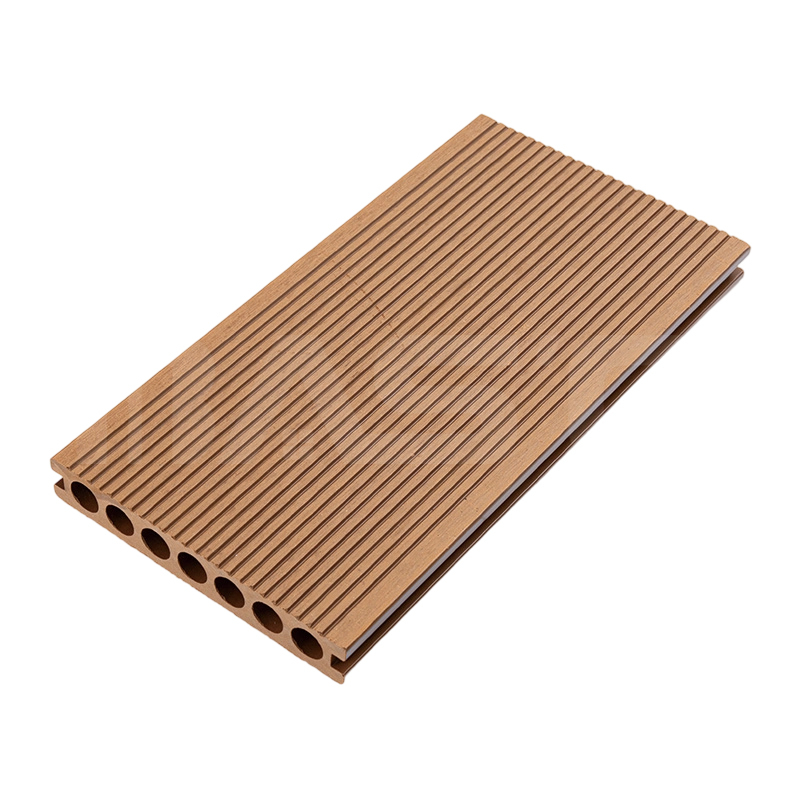

Material Composition and Durability of WPC Hollow Decking

WPC (Wood-Plastic Composite) hollow decking combines recycled wood fibers with thermoplastics, offering a balance of strength, flexibility, and weather resistance. The proportion of wood fiber and plastic affects the board's density, hardness, and resistance to UV exposure, moisture, and termite damage.

| Composition Ratio | Performance Characteristic | Application Suggestion |

|---|---|---|

| 60% wood fiber / 40% plastic | Enhanced natural wood feel, moderate durability | Residential decks with light to moderate traffic |

| 50% wood fiber / 50% plastic | Improved weather resistance, lower maintenance | Commercial decks and high-traffic areas |

| 40% wood fiber / 60% plastic | Maximum durability, UV and water resistant, lighter | Outdoor terraces in wet or coastal environments |

Selecting the correct composition ratio is essential for balancing cost, aesthetic, and long-term performance. WPC hollow decking boards are particularly advantageous in environments with significant temperature variations due to their dimensional stability.

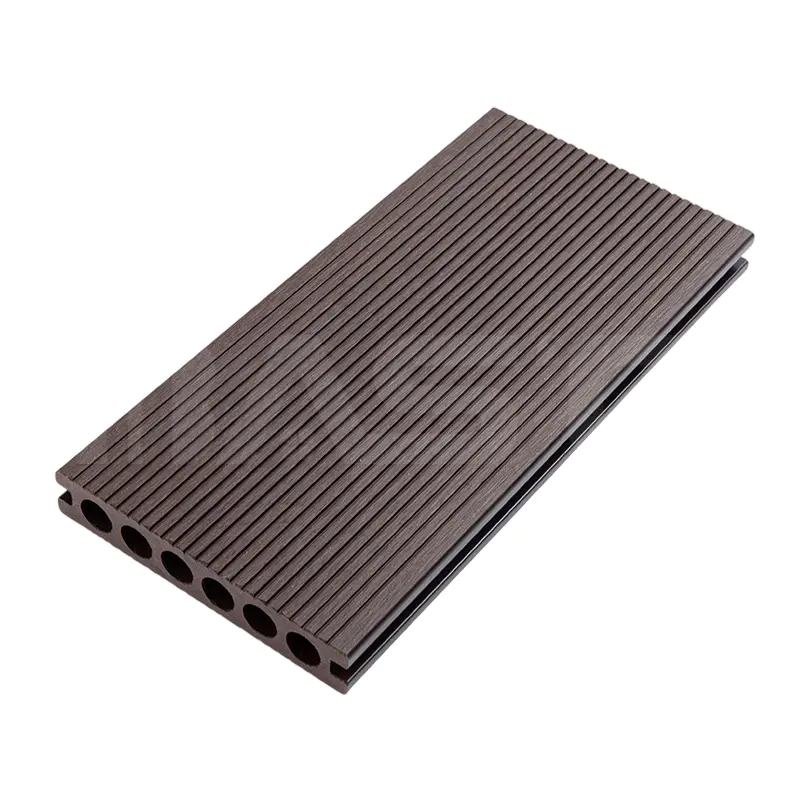

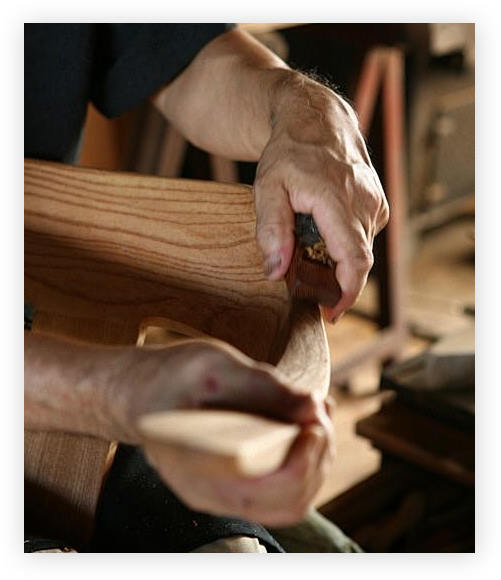

Installation Tips for Hollow Composite Decking

Proper installation techniques are crucial for maximizing the lifespan and functionality of hollow decking. Misalignment or improper support can lead to sagging or uneven surfaces. Joist spacing should generally be narrower than for solid boards to compensate for reduced thickness and rigidity.

- Use hidden deck fasteners or clips designed for hollow boards to ensure secure attachment without surface penetration.

- Leave consistent expansion gaps between boards to accommodate thermal expansion and contraction.

- Ensure joists are properly leveled and supported, as hollow boards are more susceptible to deflection under heavy loads.

- Pre-drill screw points in high-density WPC boards to prevent surface splitting.

Maintenance Strategies for WPC Hollow Decking

Although hollow composite decking requires less maintenance than traditional wood, proper care ensures longevity and aesthetic appeal. The hollow design promotes water drainage but also requires attention to debris accumulation inside the cavities.

- Regularly sweep and rinse the deck surface to prevent mold or mildew buildup inside hollow channels.

- Use mild soap and soft brushes to clean stains or surface dirt without scratching the composite material.

- Inspect hidden fasteners and clips to ensure boards remain securely attached, especially after seasonal temperature changes.

- Apply UV-protective coatings if the boards are exposed to direct sunlight to maintain color and reduce surface weathering.

Following these practices, WPC hollow decking boards can maintain performance, aesthetic appeal, and structural integrity for more than 15 years, even in outdoor, high-traffic environments.

Español

Español