Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

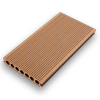

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

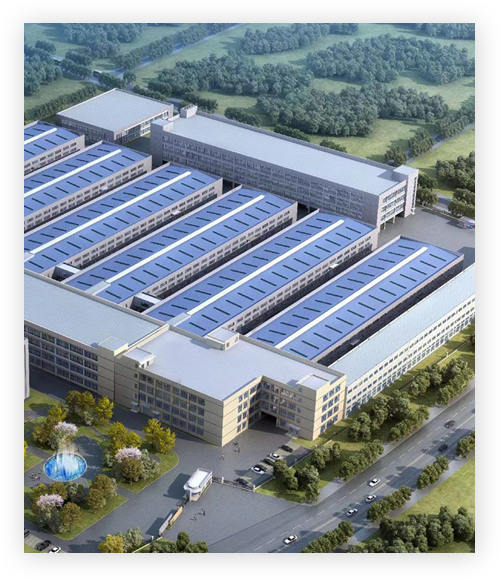

Export experience

0+

-

Production lines

0+

-

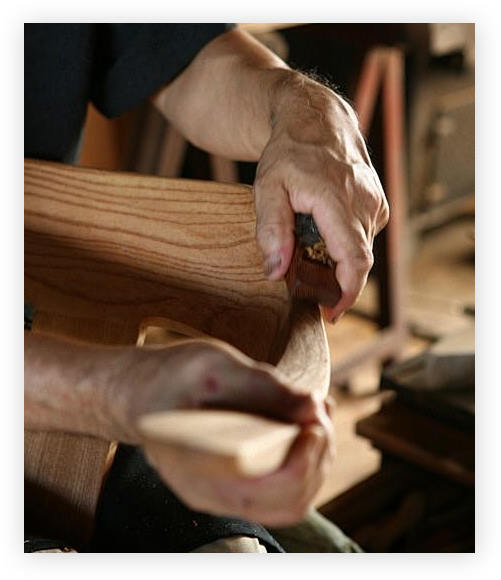

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

Optimizing Joist Spacing for Load Distribution

Proper joist spacing is critical for ensuring that decks and floors can support expected loads without sagging or structural stress. While common spacing intervals range from 12 to 24 inches, factors such as decking material, joist size, and intended use influence the ideal spacing. Narrower spacing increases load capacity and stability, especially for softer wood or composite decking, whereas wider spacing can be used for stronger materials but requires careful calculation to prevent deflection over time.

Material Selection and Durability Considerations

Selecting the right material for joist systems affects both longevity and performance. Wood joists provide natural strength and are often used for residential projects, but they require treatment against moisture, insects, and decay. Steel joists offer superior load-bearing capacity and are resistant to warping, making them suitable for commercial structures. Composite joists combine the aesthetic of wood with enhanced durability, resisting moisture, UV damage, and insect infestation. Each material choice should consider the environment, load requirements, and maintenance expectations.

Joist Orientation and Structural Alignment

The orientation of joists relative to beams, floorboards, or decking boards directly influences structural stability. Joists must be installed perpendicular to deck or floor boards to evenly distribute loads and prevent excessive bending. Alignment with supporting beams is crucial to avoid uneven weight distribution that can lead to long-term deformation or failure. In multi-level or raised decks, proper joist alignment ensures that the structure remains level and stable under variable loads.

Impact of Joist Size and Cross-Section

The dimensions of a joist—height, width, and cross-sectional shape—affect its stiffness and load-bearing capacity. Taller joists provide greater resistance to bending, while wider joists offer enhanced stability against lateral movement. Engineers often calculate joist deflection limits based on the intended application, considering factors such as span length and live load. Choosing the appropriate joist size prevents structural sagging and ensures safety for both residential and commercial decks or flooring systems.

Environmental Factors and Weather Resistance

Joist systems used outdoors or in humid environments must resist moisture, temperature fluctuations, and potential corrosion. Wooden joists require pressure treatment or sealing to prevent rot, while steel joists may need galvanization or protective coatings. Composite joists are inherently resistant to moisture and UV exposure. Understanding the environmental conditions where the joist system will be installed helps ensure long-term durability and minimizes maintenance requirements.

Comparing Load-Bearing Capacity of Different Joist Materials

| Joist Material | Span Capacity | Advantages | Maintenance Considerations |

|---|---|---|---|

| Wood | Short to medium spans | Natural look, easy to cut and shape | Requires sealing or treatment against rot and insects |

| Steel | Long spans, high load | Strong, resistant to warping and bending | May require anti-corrosion coating in outdoor settings |

| Composite | Short to medium spans | Resistant to moisture, insects, and UV | Minimal maintenance, occasionally cleaning required |

Energy Efficiency and Airflow Considerations

Joist spacing and orientation also influence energy efficiency and ventilation under flooring or decking systems. Properly designed joist systems allow air to circulate beneath the floor or deck, reducing moisture buildup and improving thermal performance. This contributes to the overall comfort of the building and can enhance insulation efficiency, especially in elevated decking or raised floor applications.

Installation Tips for Consistent Performance

During installation, consistent leveling and secure attachment to beams or support structures are essential for optimal joist performance. Using joist hangers, brackets, or specialized fasteners ensures stability and minimizes deflection. Pre-measuring and marking spacing points, verifying alignment, and using a level during installation prevent structural issues and reduce the risk of long-term sagging or misalignment in both residential and commercial projects.

Long-Term Maintenance and Inspection

Regular inspection of joist systems can prevent deterioration and maintain structural safety. Wooden joists should be checked for signs of rot, cracks, or insect damage, while steel joists require monitoring for rust or corrosion. Composite joists, though low-maintenance, should still be cleaned periodically to remove debris and prevent surface staining. Identifying potential issues early helps extend the lifespan of the joist system and avoids costly repairs.

Español

Español