Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board material, access difficulty, and regional contractor rates. For a typical 300-square-foot deck, expect...

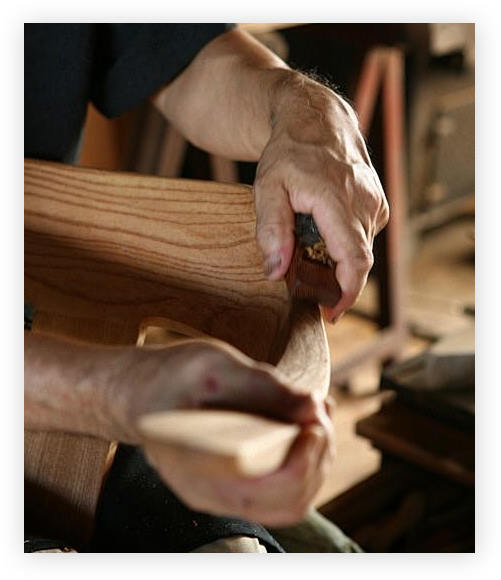

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

Export experience

0+

-

Production lines

0+

-

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical 150-foot vinyl fence installation costs $2,550-6,000, including materials, labor, posts, gates, and...

READ MORE -

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite materials require specific expansion gaps (typically 1/4 inch) and hidden fastening systems to accommod...

READ MORE

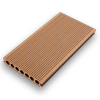

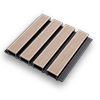

Material Considerations for Decking Edge Trim

Selecting the right material for decking edge trim is crucial for durability, performance, and aesthetic cohesion. Wood edge trims offer a natural finish that complements traditional timber decks, but they require proper sealing and maintenance to prevent moisture absorption and warping. Composite edge trims combine wood fibers with polymers, providing resistance to rot, UV exposure, and insect damage, making them ideal for high-traffic areas. PVC edge trims are lightweight, corrosion-resistant, and easy to maintain, suitable for decks exposed to harsh weather conditions or poolside environments.

Matching Edge Trim to Decking Boards

For a seamless and professional finish, the color, texture, and profile of decking edge trim should closely match the decking boards. Wood trims can be stained or painted to align with natural timber boards, while composite trims are manufactured in colors and finishes that replicate popular decking options. PVC trims typically come in neutral shades or can be coated to match custom deck designs. Ensuring a precise match enhances the visual continuity of the deck and prevents a disjointed appearance along edges.

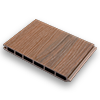

Durability and Weather Resistance

Decking edge trims must withstand environmental exposure, including rain, UV rays, and temperature fluctuations. Wood trims need protective coatings or treatments to resist moisture and reduce the risk of cracking or splitting. Composite trims inherently resist warping and fading, while PVC trims offer excellent resistance to corrosion and chemical exposure. Understanding the environmental conditions where the deck is installed helps determine the most suitable material for long-lasting performance.

Installation Techniques and Compatibility

Correct installation of edge trims ensures both aesthetics and functionality. Wood edge trims are typically nailed or screwed into place, sometimes requiring pre-drilled holes to prevent splitting. Composite trims often use hidden fasteners or specialized clips to secure the trim without visible hardware. PVC trims can be adhered with weatherproof adhesives or mechanically fixed depending on board thickness. Compatibility between the edge trim and decking material, including thickness and board type, is essential to avoid gaps, misalignment, or uneven edges.

Comparing Edge Trim Options for Different Deck Materials

| Edge Trim Type | Best Suited Deck Material | Durability Features | Installation Method |

|---|---|---|---|

| Wood Edge Trim | Timber Decks | Can be treated for rot, UV and moisture resistance | Nailed or screwed, sometimes pre-drilled |

| Composite Edge Trim | Composite Decking | Resistant to warping, splitting, and UV fading | Hidden fasteners or specialized clips |

| PVC Edge Trim | PVC or outdoor decks exposed to moisture | Corrosion-resistant, lightweight, low maintenance | Adhesive or mechanical fixing |

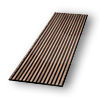

Aesthetic and Functional Benefits

Beyond protection, decking edge trims contribute significantly to the overall aesthetic of a deck. Smooth, uniform edges create a polished finish and hide raw board edges that might otherwise splinter or deteriorate. Additionally, edge trims improve safety by reducing sharp or uneven surfaces along the perimeter, especially around pool decks or terraces. Selecting the right trim ensures both visual appeal and practical functionality in outdoor spaces.

Maintenance Considerations

Maintenance needs vary depending on the trim material. Wood trims may require periodic staining or sealing to preserve appearance and prevent moisture damage. Composite trims generally only need cleaning to remove debris, while PVC trims are largely maintenance-free and can be cleaned with mild detergents. Understanding the maintenance requirements of each edge trim type ensures the deck retains its finish and performance for years to come.

Conclusion

Choosing the right decking edge trim is essential for enhancing both the appearance and longevity of wood, composite, or PVC decks. By considering material properties, compatibility, installation methods, durability, and maintenance, homeowners and builders can select trims that provide a professional, safe, and low-maintenance finish for any decking project.

Español

Español