Labor costs to replace deck boards typically range from $4 to $12 per square foot, with most homeowners paying $6-8 per square foot for standard removal and installation. Total labor charges depend on deck size, board ma...

READ MOREGREEN MATERIALS FOR SUSTAINABLE DEVELOPMENT

-

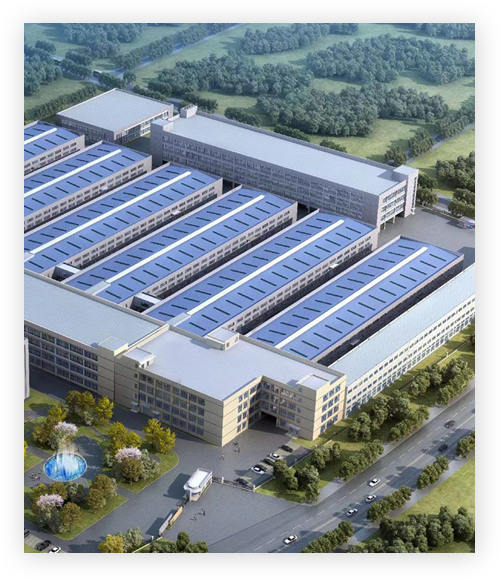

Export experience

0+

-

Production lines

0+

-

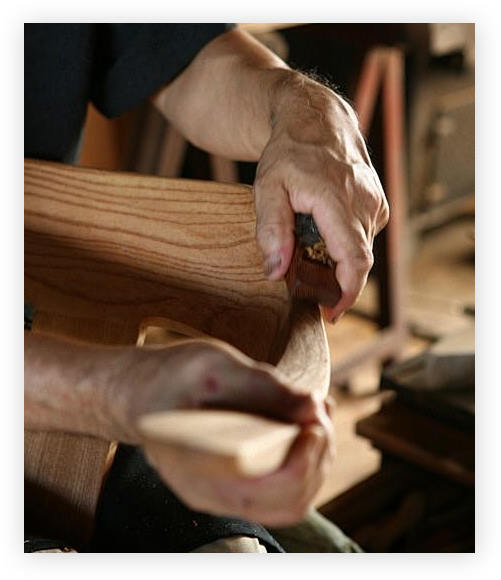

Regenerated Wood

0%

-

Exporting country

0+

-

-

Vinyl fence prices range from $17 to $40 per linear foot installed, with material costs alone averaging $8 to $20 per foot. Total project costs depend on fence style, height, quality grade, and site conditions. A typical...

READ MORE -

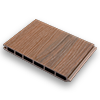

Building a composite deck involves creating a proper foundation, constructing a level frame, and installing composite boards with manufacturer-specified fasteners and spacing. Unlike traditional wood decks, composite mat...

READ MORE -

Wood does absorb sound, but its effectiveness is limited compared to specialized acoustic materials. Solid wood typically absorbs only 5-15% of sound energy, making it insufficient for serious soundproofing without addit...

READ MORE

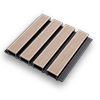

Optimizing Sound Absorption with Acoustic Slat Wood Wall Panels

Acoustic slat wood wall panels are designed to control sound reflections in indoor environments without compromising aesthetics. Their linear slat structure allows sound waves to pass through gaps and reach absorptive backing materials, reducing echo and reverberation. The spacing and thickness of the slats directly influence the panels' acoustic performance, with narrower spacing providing higher-frequency absorption and wider spacing improving low-frequency control.

Installing acoustic slat panels on large wall surfaces can significantly enhance speech intelligibility in auditoriums, conference rooms, and recording studios. Panels can be mounted with either direct adhesive, clips, or hidden brackets to ensure alignment and maintain consistent gaps between slats for optimal performance.

- Combine slat panels with fabric-wrapped acoustic cores to improve mid-frequency absorption.

- Ensure consistent airflow behind panels to avoid reducing sound absorption efficiency.

- Use staggered joint installation to prevent sound leakage through seams.

- Regularly inspect and clean panels to maintain surface integrity and acoustic function.

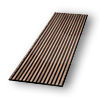

Material Considerations for Decorative Acoustic Wall Panels

Decorative acoustic wall panels combine sound absorption with aesthetic appeal. Material choice affects both performance and appearance. Common options include engineered wood, composite materials, and high-density MDF with perforated surfaces.

| Material | Acoustic Performance | Visual Options |

|---|---|---|

| Engineered Wood | High mid-frequency absorption | Natural wood finishes, stains, and laminates |

| Composite Material | Balanced frequency absorption, moisture-resistant | Custom colors and textures |

| High-density MDF | Excellent low-frequency control when perforated | Paintable surfaces, perforated designs |

Choosing the right material depends on room usage, desired frequency absorption, and design objectives. Combining multiple materials can address both visual and acoustic goals simultaneously.

Installation Techniques for Enhanced Acoustic Performance

Correct installation is critical to maximize acoustic efficiency. Even high-quality panels can underperform if gaps, mounting methods, or backing materials are improperly handled. Panels should be installed on walls or ceilings with precise spacing to create channels for sound waves to reach absorptive cores.

- Use resilient mounting clips or furring strips to isolate panels from rigid walls and reduce vibration transfer.

- Apply acoustic insulation behind panels for enhanced low-frequency absorption in large spaces.

- Maintain a minimum gap of 10–15 mm between the panel back and the wall surface to allow air movement.

- Align slats in parallel for uniform absorption or create alternating patterns to manage diffused reflection.

Maintenance and Longevity of Acoustic Wall Panels

Long-term performance of decorative acoustic wall panels depends on regular maintenance and environmental control. Dust, moisture, and mechanical impact can degrade both visual appeal and sound absorption.

- Clean surfaces with soft, dry cloths or low-pressure vacuuming to remove dust accumulation.

- Inspect for warping or separation between slats and adhesive, especially in high-humidity areas.

- Reapply protective finishes on wood-based panels periodically to prevent surface cracking.

- Ensure that panels are not exposed to direct water or excessive heat, which can compromise both acoustic properties and aesthetics.

When properly installed and maintained, acoustic slat wood wall panels can sustain their performance and decorative value for over a decade, making them a practical investment in professional and residential spaces alike.

Español

Español